Ayomide O. Omojokun 1*; Anthony O. Ojokoh 2; Felix A. Akinyosoye 1

1, Department of Microbiology, Federal University of Technology, Akure, Nigeria

2, Department of Biotechnology, Federal University of Technology, Akure, Nigeria

E-mail:

aoomojokun@gmail.com

Received: 11/06/2021

Acceptance: 03/09/2021

Available Online: 06/09/2021

Published: 01/10/2021

Manuscript link

http://dx.doi.org/10.30493/DAS.2021.290155

Abstract

This study is designed to determine the outcomes of fermentation and extrusion on the dietary ingredients of cassava and African yam bean blends. For this purpose, blends of cassava and African yam beans were formulated as follows: A= 100:0; B= 90:10; C= 80-20; D= 70-30; E= 60:40; F= 50:50, ratio cassava: African yam beans respectively. A portion of each blend was fermented spontaneously for 120 hours, another portion was extruded, and the third portion was fermented and extruded while the last portion served as control (untreated). Proximate mineral and amino acid analyses were carried out on the samples. Fermented extruded blends had the highest protein (14.82-51.86 %). Extruded blend D had the lowest fiber (0.17 %), while the raw blend C had the highest fiber (2.89 %). Carbohydrate was the lowest in fermented extruded blends and ranged between 39.4 to 80.26 %. Moisture was highest in fermented extruded blend C (9.72 %). Raw blends had the highest ash contents (2.71-3.41 %). Fat content was the highest in fermented F (0.034 %). The mineral composition showed that fermented extruded blends had the highest sodium (18.40- 43.9 ppm), fermented C had the highest calcium (65.60 ppm), fermented extruded C had the highest potassium (55.80ppm), and fermented extruded E had the highest magnesium (7.34 ppm). Extruded D had the highest zinc (0.416 ppm). Fermented A had the highest iron content (1.052 ppm). The fundamental amino acids analysis revealed that histidine, isoleucine, leucine, lysine, methionine, phenylalanine, threonine, tryptophan, and valine increased after fermentation extrusion. Conclusively, fermentation and extrusion of cassava and African yam bean blends enhanced the nutritional value of the food samples at wide-ranging proportions.

Keywords: Manihot esculenta, Sphenostylis stenocarpa, Fermentation, Extrusion, Amino acids, Mineral contents

Introduction

Cassava (Manihot esculenta Crantz) is an essential staple food for the livelihood of many people, predominantly the poor communities in Sub-Saharan Africa, Latin-America, and Asia [1]. Presently, cassava is rapidly changing from a usual subsistent crop found on the field of peasant farmers to a marketable crop grown in plantations. The boost in consumption of this crop is credited to it being a cheap source of edible carbohydrates that could serve in the human diet as well as animal feeds after apt processing.

African yam bean (AYB) (Sphenostylis stenocarpa Hochst ex. A. Rich.) Harms is an underutilized tropical African tuberous legume. The arable tuberous legume is imperative in the majority of native African food cultures and in peasant agriculture. It has been established that legumes possess 2-3 times the amount of protein in cereals, and no other plant food has been confirmed to be as rich as legumes in terms of protein in their natural state [2][3]. AYB is cultivated as a minor crop together with yam and cassava. AYB fills in as a security crop, and there is a tendency to meet all-year protein prerequisites whenever it is grown on a vast scale [3]. African yam bean (AYB) is immensely nourishing with elevated protein, mineral, and fiber constituents. Its protein content is detailed to be nutritionally equivalent to some frequently consumed legumes. Its amino acid profile is equivalent, if not enhanced, compared to those of cowpea, soybean, and pigeon pea [4][5][6].

The potential for incorporating African yam beans into cassava to make composite flour requires adequate processing. The need for this processing of the composite flour blends is due to the various anti-nutrients present in cassava and African yam beans, to improve the nutritional quality and shorten the long cooking time of African yam beans.

The fermentation procedure serves as a primary source of diet and nourishment for a large population and adds appreciably to food safety measures by increasing the range of fresh raw materials that can be used in the production of edible food products [7]. Fermentation augments the nutritional constituents of foods via the biological synthesis of vitamins, essential amino acids, and proteins in addition to enhancing the protein quality and fiber digestibility [8]. It also improves micronutrient bio-availability and abets the reduction of anti-nutritional dynamics [7].

Extrusion cooking is the process in which a food material containing a meager amount of water is forced and heated concurrently under mechanical shear pressure, transformed into a plastic mass, constrained through a forming die, and quickly solidified by cooling. The usage of high-temperature short-time practice for food processing, such as extrusion, is believed to be valuable in terms of elevated output and nutrient preservation [9]. The extrusion process has become an ever more accepted procedure in food industries to develop novel products, including snacks and baby foods. Food extrusion is used to convert a diversity of constituents to transitional products or ready to use ones, such as breakfast cereals, snacks, infant food, instant soups, breadcrumbs, finished vegetable protein, meat substitute, modified starches, confectionery, pasta, powdered beverages, cookies, granola, cones, etc. [10]. A major advantage of extrusion cooking is producing various extruded products from low-cost raw materials under nominal processing times [11].

Since there is little information on the outcome of fermentation and extrusion on dietary constituents of fermented and extruded blends of cassava and African yam beans, this work is aimed at improving the nutritional quality of cassava by complementing it with African yam beans at varying ratios. These will further be subjected to fermentation and extrusion processes to determine which variables will give the most desirable results.

Material and methods

Source of raw materials

Freshly harvested matured cassava (Manihot esculenta) tubers were obtained from a farm in the Federal University of Technology, Akure, Nigeria. Fresh mature African yam beans (Sphaerostylis stenocarpa) were acquired from an open market in Akure, Nigeria. The samples were transported to the Department of Microbiology laboratory.

Sample preparation

The cassava tubers were washed with clean water and peeled. They were transferred into a clean plastic container with a cover. African yam bean seeds were also cleaned by removing dirt, stones, and unwanted seeds. Then, the seeds were washed and dried.

Formation of blends

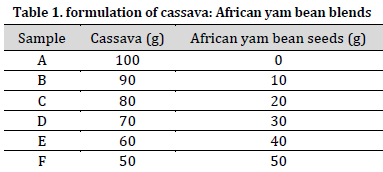

Cassava and African yam beans were mixed in varying ratios (Table 1). The blends were kept in sterile air-tight plastic containers and properly labeled as A, B, C, D, E, E, and F. This was done following [12] method.

Processing of the flour blends

The cassava and African yam bean blends were divided into four parts. A portion of the blends was only fermented spontaneously. The second part was only extruded. The third portion was fermented and extruded, while the last portion was left untreated (the control).

Fermentation

Cassava and African yam bean blends were fermented by adding 2 liters of sterile water into 1kg of each blend in sterile containers. The samples were tightly covered and left to ferment for 120 hours. The fermentation process was ended by drying in the oven at 55 °C for 24 hours.

Extrusion

Cassava and African yam bean blends were extruded with the use of a Brabender 20DN. This process was done as described by [13].

Analysis

Proximate analysis

The samples’ proximate analysis (moisture, ash, crude protein, carbohydrate, fat, and crude fiber contents) was achieved via the customary scheme of [14]. All determinations were done in triplicates and reported in percentage.

Mineral analysis

A 1g of each sample was weighed into a crucible and transferred into muffle furnace pre-set at 5500C for 120 minutes. The ash was distilled with 10 ml of 20% nitric acid and placed on the hot plate at 30 °C for one hour. The content was filtered into 100 ml standard flask and made up to volume with distilled water. The concentration of calcium, magnesium, zinc, and iron was measured using an Atomic Absorption Spectrophotometer (GBC Scientific Equipment Pty. Ltd), whereas flame photometry technique was utilized for potassium and sodium [14].

Amino acids analysis

The determination of the amino acid profile was carried out following two steps. Firstly, the hydrolysis of the samples to individual amino acids. This step was followed by the quantitative assessment of the amino acids in the hydrolysate. The samples were first defatted using a soxhlet extraction apparatus, followed by hydrolysis of samples. A 7 ml of HCl was added to the samples, followed by extraction oxygen with nitrogen gas. They were vacuum dried in a rotary evaporator before loading into a Technicon Sequential Multisample (TSM) Amino Acid Analyzer (TSM-1 Technicon Instrument Basingstoke, UK) as described by [15].

Statistical analysis

All data obtained were analyzed using Analysis of Variance (ANOVA) with the Statistical Package for Social Sciences (SPSS) version 16. Results were reported as mean ± SD.

Results and Discussion

Proximate composition of cassava: African yam bean blends

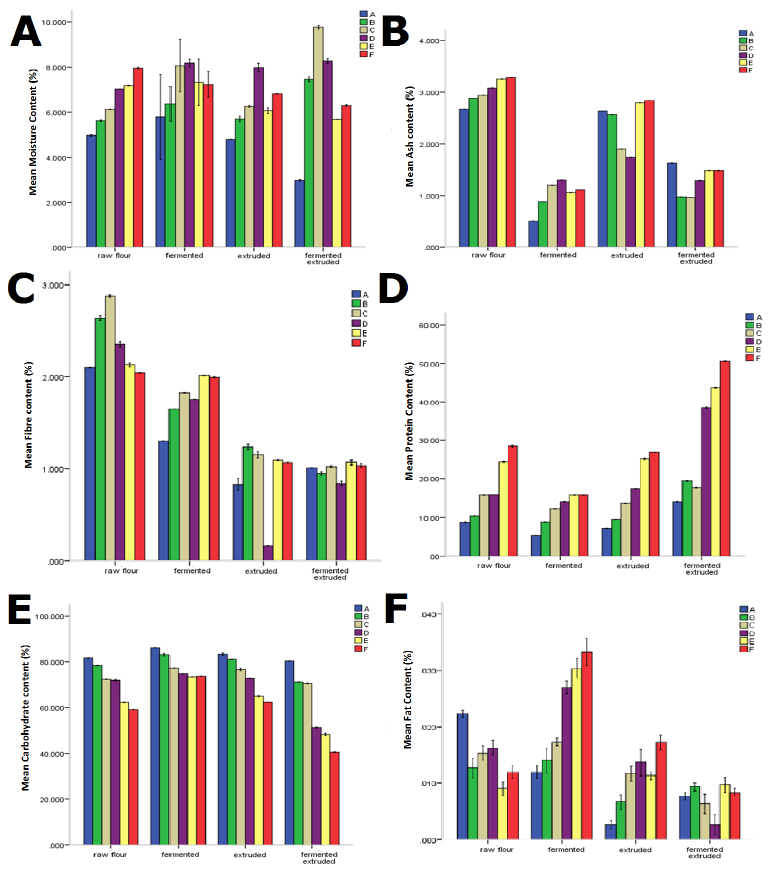

The moisture constituent of the raw blends ranged from 5.01 to 8.16%. Fermented blends had moisture content that ranged from 5.92 to 8.05%. The extruded blends had values that ranged from 4.88 to 7.95%, while the least moisture content was observed in sample A of fermented extruded blends (2.49%) (Fig. 1 A). Moisture is one of the majorly considered criteria of various food products for its impact on food value, processing activities, and shelf life. The steady moisture content of the raw blends before fermentation and extrusion shows the storage preference and shelf life of the samples if suitably packaged [12][16]. Inconsistency in the moisture content of the samples is a consequence of the water addition during fermentation and extrusion. [17] reported that moisture content of less than 14% in extruded composite flour could enhance shelf stability and viability of such food.

The highest ash content was observed in the raw sample blends with values that ranged from 2.71 to 3.41%, while fermented blends had the least ash content, ranging from 0.57 to 1.30% (Fig. 1 B). The ash content of the extruded blends ranged from 1.72 to 2.91%, while fermented extruded blends had values ranging from 0.85 to 1.62%. Reduction in the ash content of the fermented blends agrees with the findings of several researchers who have detailed various reductions in the ash content of fermented food samples. [12] reported analogous reductions in ash constituents of fermented unripe plantain and cowpea blends. Similar outcomes were also obtained by [18] and [19]. [20] also reported a decrease in ash content of extruded sorghum malt and Bambara groundnut.

Raw blends had the highest fiber content ranging from 2.18 to 2.89%. There was no considerable disparity in the fiber content of extruded blends and fermented extruded blends, with extruded D having the least value (0.17%) (Fig. 1 C). Fiber is essential in the human diet since it enhances bowel movement, prevents obesity and constipation, and reduces the risk of colon cancer [17]. The reduction in fiber content could be attributed to the capacity of the fermenting microbes to breakdown the crude fiber of the fermented blends via hydrolyzing and oxidizing enzymes entailed in the transformation of resident compounds in the food blends into functional compounds [21] and copious fabrication of unrefined acids ensuing from fermentative dissimulation of carbohydrate [22].

It was deduced that fermented extruded blends had the highest protein content (14.82-51.86%) compared to other blends of similar ratios(Fig. 1 D).Increase in protein content was observed with increase in the addition of African yam beans. There were no substantial variations in protein content of raw blends and extruded blends. The enhancement in protein content of fermented extruded blends could be as a result of the synergistic impact of both fermentation and extrusion.

Some researchers have detailed a modest boost in the protein content by extrusion cooking owing to the rise in digestibility. That can be owed to the dormancy of enzyme inhibitors and denaturation of protein present in unprocessed components that render them to attack enzymes [23]. [17] reported an increase in protein content with the increase of African yam beans content during the production of extruded African yam beans based ready to eat snack. A similar result was also obtained by [24] in the use of African yam beans and shrimps in the production of maize-based cereal blends.

Fermented extruded blends had the lowest carbohydrate content ranging from 39.4 to 80.26%. A steady decrease in carbohydrate content of the food blends was observed with the decrease of cassava flour content in the blend (Fig. 1 E).

The highest fat content was found in the fermented F blend (0.034%), while the least was observed in the fermented extruded D blend (0.003%) (Fig. 1 F). There was an increase observed in the fat content of the fermented blends except for A blend. The rise in the fat content might be due to the increase in the microbial mass (cell membrane lipids), the production of extracellular lipase via lipolytic microbes, microbial oil emission into the fermenting medium, and other metabolism products [25]. Reduced fatty content of the extruded blends and fermented extruded blends could be owed to lipid oxidation. Oxidation of lipid can diminish food quality by decreasing the quantity of vital fatty acids, such as linolenic acid. These long-chained fatty acids are vulnerable to oxidation due to the high temperature applied during extrusion. [19] reported a decrease in the fat content of sorghum malt and Bambara groundnut-based extrudates. However, the reduction in fat content due to extrusion cooking could increase product stability and storability by reducing lipid rancidity. Furthermore, extrusion deactivates enzymes that can advance oxidation, thereby making lipids held in starch to be less liable to oxidation [19].

Mineral composition of fermented and extruded cassava: African yam bean blends

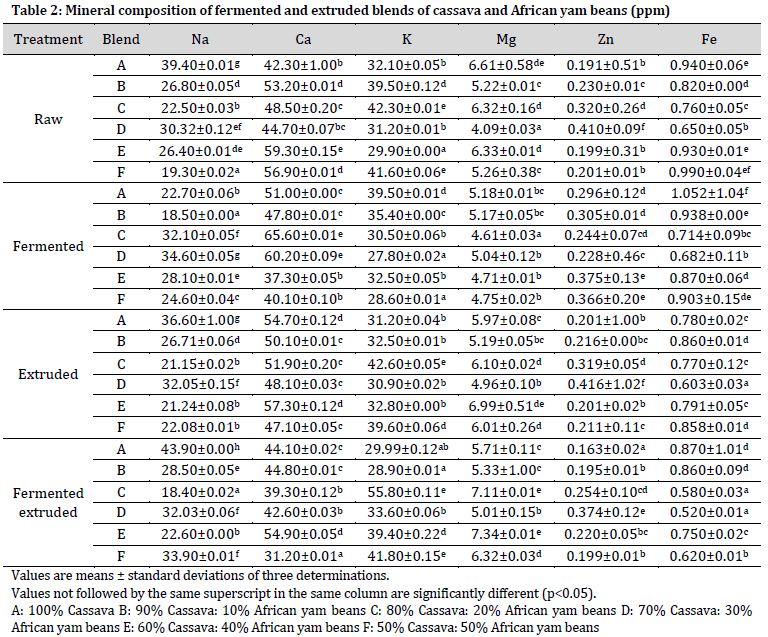

The mineral composition of the studied blends is mentioned in (Table 2). Fermented extruded A had the highest sodium (Na) content of 43.90 ppm, while fermented extruded C had the lowest sodium content. The highest calcium (Ca) content was observed in fermented C with 65.60 ppm, while fermented extruded F had the lowest calcium content with 31.20 ppm.

Fermentation increased the sodium content of blends C, D, E, and F. On the other hand, only extruded blends D and F had higher sodium content compared to the control. Thus, extrusion did not have a significant impact on the sodium content. The combined application of both fermentation and extrusion greatly increased the sodium content in all the samples except for C, which was lower than the control.

Fermentation also increased the calcium content in A, C, and D, while fermented blends B, E, and F showed reduced calcium content as compared to the control. Extruded A, C, and D blends had higher calcium content than the control, while B, E, and F had lower calcium. Among the fermented extruded blends, only A had a higher calcium content compared to control. This implies that fermentation and extrusion did not impact desired significant changes in the samples’ calcium levels.

Only Fermented blends A and E had higher potassium content compared to control, while potassium decreased significantly in B, C, D, and F blends after fermentation. There was a slight increase in the potassium content C extruded blend, while that of E increased significantly. On the other hand, potassium levels in the extruded A, B, D, and F showed a decreased potassium content as compared with the control. The fermented extruded C, D, E, and F showed significant increases in potassium, unlike A and B, which had lower potassium contents.

Fermented extruded blends B, C, D, E, and F showed a significant increase in magnesium content. Extruded blends D, E, and F also had a high amount of magnesium. On the other hand, fermentation alone resulted in a relatively lower Mg content. This observation shows that the application of both fermentation and extrusion had a synergistic effect in improving the magnesium content of the blends.

Fermentation increased the zinc content of the blends A, B, E, and F. Extrusion also significantly impacted the zinc content of the blends A, D, E, and F. Samples subjected to both fermentation and extrusion did not show improved zinc content.

Fermented A, B, and D; extruded B, and C, and fermented extruded B showed an increase in iron content. Other samples recorded reduced amount of iron. This shows that fermentation and extrusion of the samples did not result in appreciable improvement of the iron content of the samples.

[26] detailed a boost in minerals during fermentation of corn. The extrudates had lower values for mineral composition when compared to the raw blends. These results differ from the findings of [27] who reported an increase in mineral composition of extruded pigeon pea and unripe plantain blends. Results of the mineral composition of the food blends is different from the report of [28] in which fermentation increased the magnesium, potassium and calcium contents of low and medium hydrogen cyanide containing cassava.

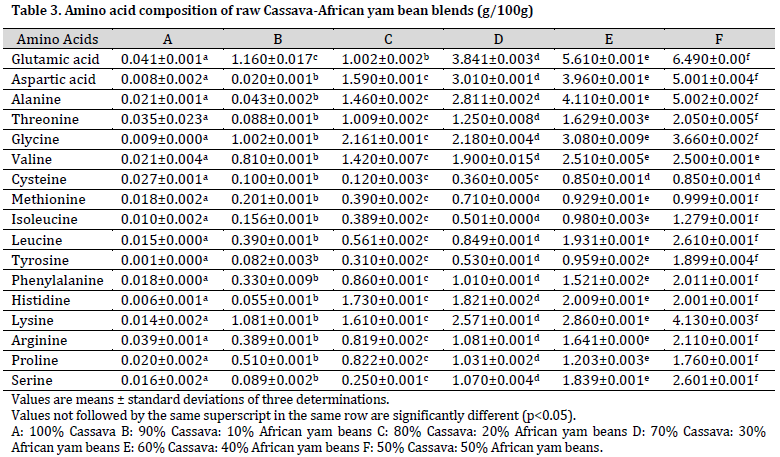

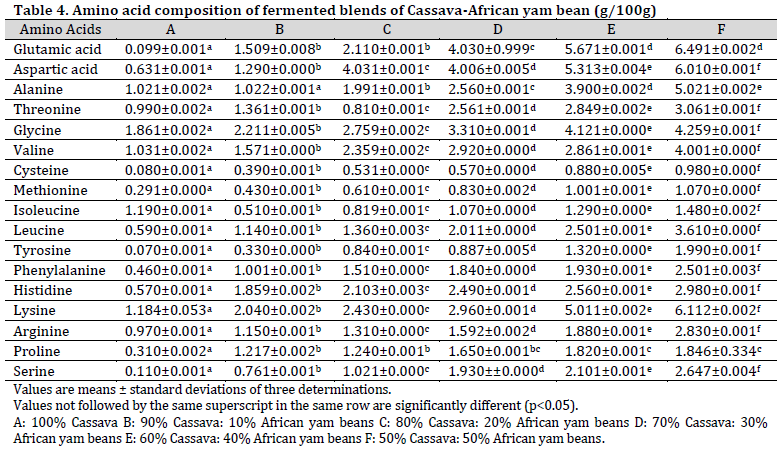

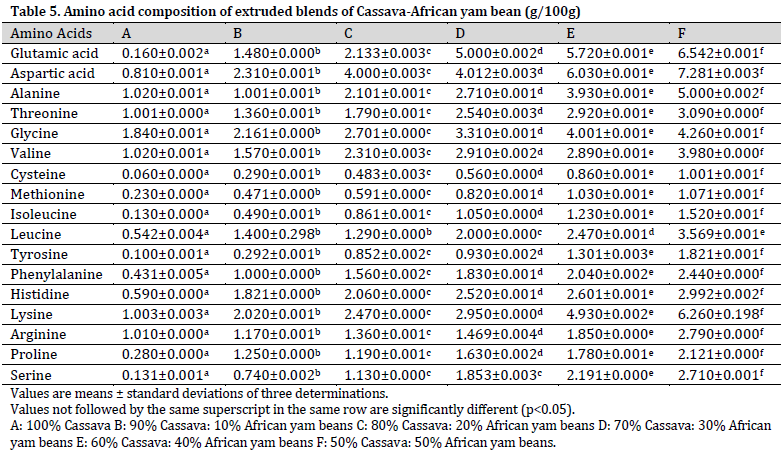

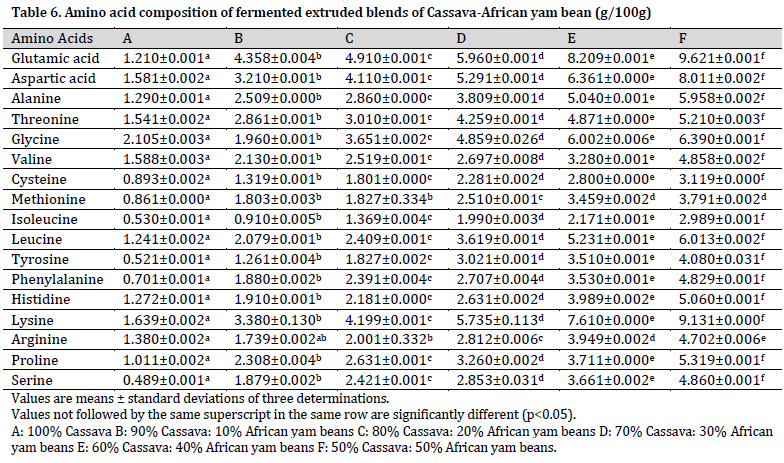

Amino acid composition of fermented and extruded cassava: African yam bean blends

The amino acid composition of the studied blend can be seen in (Tables 3 – 6). Blending African yam beans with cassava led to increase in the amino acid profile of the samples. The result obtained revealed that blending of cassava with African yam beans prior to fermentation and extrusion marginally increased the amino acid composition of cassava. A similar increase in amino acid of rice flour supplemented with Amaranth was reported by [29]. The increase in the amino acid composition of the fermented blends is in agreement with some researchers who have reported such an increase following the fermentation of some food samples. [30] reported an increase in lysine and tryptophan contents of fermented maize. However, the increase in amino acids contradicts the findings of [27], who reported a decrease in amino acid contents of extruded pigeon pea and unripe plantain blends. The currently obtained results are also contrary to the report of [31], who stated a loss in essential amino acids of extruded whole grain flours of quality protein maize (QPM) and typical maize cultivars. Overall, the nutritional content of plant protein is usually improved by moderate extrusion cooking criteria due to a rise in digestibility [19].

Conclusions

Blending of African yam beans with cassava flour increased the dietary constituents of the food. The higher the amount of African yam bean flour added to the cassava, the better the protein and amino acid composition. Furthermore, fermentation and extrusion further improved the overall nutritional constituents of cassava and African yam bean blends.

References

| 1 | Chisenga SM, Workneh TS, Bultosa G, Laing M. Proximate composition, cyanide contents, and particle size distribution of cassava flour from cassava varieties in Zambia. AIMS Agric. Food. 2019;4(4):869-91. DOI |

| 2 | Aburime LC. Effect of different processing methods on the chemical composition of African yam bean (Sphenostylis stenocarpa) flours and organoleptic characteristics of their gruels. (Unpublished master’s thesis). University of Nigeria Nsukka, Nigeria. 2012. |

| 3 | George D, Pamplona R. Encyclopedia of foods and their healing power. Education and Health Library. A Guide to Food Science and diet therapy. 2005;2:83. |

| 4 | Obizoba IC, Souzey J. The nutritive value of African yam bean (sphenostylis stenocarpa): Nitrogen and mineral utilization. Ecol. Food Nutr. 1989;22(4):297-305. DOI |

| 5 | Ene-Obong HN, Carnovale E. A comparison of the proximate, mineral and amino acid composition of some known and lesser known legumes in Nigeria. Food Chem. 1992;43(3):169-75. DOI |

| 6 | Uguru MI, Madukaife SO. Studies on the variability in agronomic and nutritive characteristics of African yam bean (Sphenostylis stenocarpa Hochst ex. A. Rich. Harms). Plant Pro. Res J. 2001;6(1):10-9. |

| 7 | Oboh G. Nutrient enrichment of cassava peels using a mixed culture of Saccharomyces cerevisae and Lactobacillus spp solid media fermentation techniques. Electron. J Biotechnol. 2006;9(1): 46-49. DOI |

| 8 | Ojokoh AO, Omojokun AO. Effects of Fermentation on the Nutritional Composition of Banana and Groundnut Flour Blends. J. Appl. Life Sci. 2019:1-0., 21(3): 1-10. DOI |

| 9 | Gulatia P, Brahmaa S, Rosea DJ. Impacts of extrusion processing on nutritional components in cereals and legumes: Carbohydrates, proteins, lipids, vitamins, and minerals. Extrusion Cooking: Cereal Grains Processing. 2020:415-43. DOIs://doi.org/10.1016/b978-0-12-815360-4.00013-4 |

| 10 | Llopart EE, Drago SR, De Greef DM, Torres RL, González RJ. Effects of extrusion conditions on physical and nutritional properties of extruded whole grain red sorghum (sorghum spp). Int. J. Food Sci. Nutr. 2014;65(1):34-41. DOI |

| 11 | Akhtar J, Malik S, Alam MA, Student MT, Allahabad S. Extrusion technology used for novel Foods Production. Int. J. Eng. Dev. Res. 2015;3(3):1-6. |

| 12 | Okhonlaye OA, Olubunmi FA. Effects of fermentation and extrusion on the proximate and organoleptic properties of cowpea-plantain flour blends. Microbiol. Res. J. Int. 2016:1-13. DOI |

| 13 | Ruiz-Gutiérrez MG, Sánchez-Madrigal MÁ, Quintero-Ramos A. The extrusion cooking process for the development of functional foods. Extrusion of metals, polymers and food products. IntechOpen. 2018. DOI |

| 14 | Association of Official Analytical Chemists. Official methods of analysis. Association of official analytical chemists. 22nd edition. Washington, D.C. 2012:35-60. |

| 15 | Nweke FN, Ubi BE, Kunert KJ. Determination of proximate composition and amino acid profile of Nigerian sesame (Sesamum indicum L.) cultivars. Niger. J Biotechnol. 2011;23:5-12. |

| 16 | Odom TC, Udensi EA, Iwe MO. Nutritional evaluation of unripe Carica papaya, unripe Musa paradisiaca and Mucuna cochichenesis weaning food formulation. Euro J Biol Med Sci. 2013 Jun;1(1):6-15. |

| 17 | Omafuvbe BO, Falade OS, Osuntogun BA, Adewusi SR. Chemical and biochemical changes in African locust bean (Parkia biglobosa) and melon (Citrullus vulgaris) seeds during fermentation to condiments. Pak J Nutr. 2004;3(3):140-5. |

| 18 | Laetitia MM, Joseph HD, Joseph D, Christian M. Physical, chemical and microbiological changes during natural fermentation of \”gowé\”, a sprouted or non sprouted sorghum beverage from West-Africa. Afr J Biotechnol. 2005;4(6):487-96. |

| 19 | Filli KB. Physicochemical properties of Sorghum malt and Bambara Groundnut Based extrudates. J. Food Sci. Technol. Nepal. 2016;9:55-65. |

| 20 | Obueh HO, Ikenebomeh MJ. Bioethanol production and compositional changes during fermentation of cassava processing wastes from a local cassava mill. Int. J Cur. Res. Biosci. Plant Biol. 2014;1(4):43-51. |

| 21 | Akinyele BJ, Olaniyi OO, Jeff-Agboola YA. Effect of fermentation on chemical composition of cassava peels. Asian J. Plant Sci. Res. 2017;7(1):31-8. |

| 22 | Oseni OA, Akindahunsi AA. Some phytochemical properties and effect of fermentation on the seed of Jatropha curcas L. Am J Food Technol. 6(2):158-65. DOI |

| 23 | Sotunde AJ, Awofadeju OF, Olapade AA. Production and characterisation of extruded African yam bean based ready-to-eat breakfast product. j. res. for. wildl. environ. 2021;13(1):172-87. |

| 24 | Aminat O, Ngozi U, OO L. The Use of African Yam Beans and Shrimps in the Production of Maize-Based Cereal Blends. Nutri. Food Sci. 2012;2:155 |

| 25 | Oboh G, Akindahunsi AA, Oshodi AA. Nutrient and anti-nutrient contents of Aspergillus niger-fermented cassava products (flour and gari). J. Food Compost. Anal. 2002;15(5):617-22. DOI |

| 26 | Sokrab AM, Ahmed IA, Babiker EE. Effect of fermentation on antinutrients, and total and extractable minerals of high and low phytate corn genotypes. J. Food Sci. Technol. 2014;51(10):2608-15. DOI |

| 27 | Anuonye JC, Jigam AA, Ndaceko GM. Effects of extrusion-cooking on the nutrient and anti-nutrient composition of pigeon pea and unripe plantain blends. J. Appl. Pharm. Sci. 2012;2(5):158-62. |

| 28 | Hawashi M, Widjaja T, Gunawan S. Solid-state fermentation of cassava products for degradation of anti-nutritional value and enrichment of nutritional value. New Advances on Fermentation Processes. IntechOpen. 2019. DOI |

| 29 | Omeire GC. Amino acid profile of raw and extruded blends of African yam bean (Sphenostylis stenocarpa) and cassava flour. Am. J. Food Nutr. 2012;2(3):65-8. |

| 30 | Mohiedeen IE, Tinay AH, Elkhalya AE, Babiker EE, Mallasiy LO. Effect of fermentation on in vitro protein digestibility, protein fractions and amino acids composition of maize (Zea mays Linnaus) cultivars. Electron. J. Environ. Agric. Food Chem. 2010;9:838-47. |

| 31 | PAES MC, MAGA J. Effect of extrusion on essential amino acids profile and color of whole-grain flours of quality protein maize (qpm) and normal maize cultivars. Rev Bras Milho Sorgo. 2004;3(1):10-20. DOI |

Cite this article:

Omojokun, A., Ojokoh, A., Akinyosoye, F. Nutritional composition of fermented and extruded blends of cassava and African yam beans flour. DYSONA – Applied Science, 2021; (): 53-63. doi: 10.30493/das.2021.290155