Nourelhouda Dekhili1

1, Department of Mechanical Engineering, Faculty of Science and Technology, University of Biskra, Algeria

E-mail:

nourelhouda8@gmail.com

Received: 02/11/2019

Acceptance: 26/01/2020

Available Online: 23/02/2020

Published: 01/04/2020

Manuscript link

http://dx.doi.org/10.30493/das.2020.103719

Abstract

Bacterial corrosion is the phenomenon where sulfate-reducing bacteria (SRB) metabolic acts help creating favorable conditions for corrosion to occur. This type of corrosion is widely observed in anaerobic industrial environments especially in petroleum pipelines and might result in severe losses in oil and gas industries. Many commercial substances are used in the petroleum industry in order to control this phenomenon. Here, we tried to evaluate the effectiveness of using Biocide 2 CHIMEC 7660 in later phase bacterial corrosion on N80 steel. In order to achieve that aim, N80 steel samples were put in an anaerobic simulation in the presence of (SRB) and after 60 days of bacterial exposure, Biocide 2 CHIMEC 7660 was added to treated samples. The experiment was then continued for another 30 days, where the surfaces of control and treated samples were studied using scanning electronic microscope (SEM) and energy-dispersive X-ray spectrometry (EDS). (SEM) scans showed an efficient removal of a large part of the deposits and colonies on treated surfaces compared to control. However, both samples (EDS) analysis illustrated the presence of oxygen and an increased amount of sulfur. Although biocide application was efficient enough to control bacterial growth and eliminate the forming residues after 60 days of exposure to (SRB), the bacterial corrosion occurred before the treatment was enough to cause damage to the studied surface. This study refers to the effectiveness of using Biocide 2 CHIMEC 7660 and emphasizes on its early application.

Keywords: Corrosion,Bacterial corrosion,Sulfate-Reducing Bacteria, Biocide, N80 Steel

Abbreviations: Sulfate-Reducing Bacteria (SRB); scanning electronic microscope (SEM); Energy Dispersive X-ray spectrometry (EDS)

Introduction

The oil industry is an important driving force of the Algerian economy. However, this industry is faced with numerous challenges. One of these challenges is bacterial corrosion. Corrosion, in general, can be defined as a phenomenon of materials degradation under the effect of the physical, chemical or electrochemical actions of the surrounding environment. Corrosion is responsible for annual costs up to 5% of the Gross National Product (GNP) of an industrial country [1][2].

The process where bacterial metabolic acts help creating favorable conditions for corrosion to occur is called bacterial corrosion [3][4]. The main bacterial type associated with this deterioration is the anaerobic Sulfate-Reducing Bacteria (SRB). In low oxygen environments and in the presence of sulfate, SRBs contribute to the mineralization of organic material by the process of sulfate reduction [4-7]. Furthermore, these bacteria are known for their exceptional enzymatic capability that allows them to grow in rather complex conditions and to adhere to various surfaces, including metallic based materials [8-10]. This bacterial corrosion is widely observed in petroleum pipelines which might result in pipes clogging and other severe losses in the oil and gas industries [11].

In order to avoid the harmful effects of BSR on metallic materials and installations, a chemical treatment with biocides is applied. The term biocide or bactericide includes all the chemicals which destroy or prevent the development of microorganisms [12]. Quaternary ammonium compounds (QUATS), formaldehyde, glutaraldehyde, acrolein, amines and diamines in addition to methylchloromethyl-isothiazolone (MCMI) and 4,5-dichloro-2-n-octyl-4-isothiazolin-3-one (DCOI) are some of the widely used compounds in industrial biocides [13][14].

The purpose of this work was to study the deposit resulting from bacterial corrosion on the surface of N80 steel samples and determine the elements contributing to the formation of this deposit. Furthermore, this study evaluated the effectiveness of the industrial biocide 2 CHIMEC 7660 in the removal of these deposits.

Material and Methods

Experimental material and biocide

The test material in this work was N80 steel which is known for its high resistance to the pressure. This has rendered it a proper material to be used during the drilling process and to ensure a normal functionality in oil wells especially in early extraction phases.

The used biocide is a commercial substance under the name Biocide2 CHIMEC 7660 (CHIMEC – Rome). This biocide is a liquid, non-oxidant, non-foaming substance with an antibacterial effect against aerobic and anaerobic bacteria which make it suitable for use on hard water and over a wide range of pH values (6-9).

Bacterial samples preparation

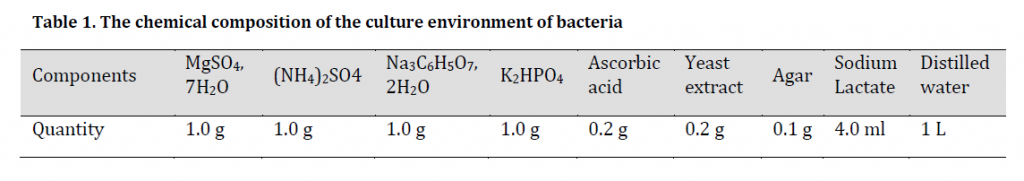

A sample of water was collected from CINA (North Industrial Complex Treatment Center), 9 km north of Hassi Messaoud (South Algeria). This sample of water comes from crude separation. To examine the presence of (SRB) in this sample, a bacterial culture medium (SRB specific) [15] was prepared (Table 1). Penicillin vials were filled with 9 ml of the prepared medium with a metal nail. The vials were plugged using proper rubber plugs, purged with nitrogen to create an anaerobic environment, and sterilized by autoclaving at 120°C for 50 minutes. Then, using a syringe, 1 ml of the water sample was injected through the septum of each vial. Then, the vials were incubated at 37 °C for 28 days. By the end of the incubation period, a blackening deposit formed in the vials with an increase in environment pH which illustrated the presence of (SRB) in the water sample.

Environment and samples preparation

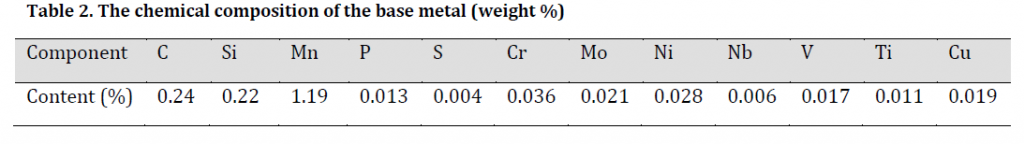

N80 oil steel pipe samples of 15 mm*13.5 mm* 5.4 mm for length, weight and thickness respectively, and with the chemical composition showed in (Table 2) were used in the experiment. The surface of the samples was rectified, cleaned, and dried.

The same bacterial culture environment shown in (Table 1) was prepared. Penicillin vials were filled with 9 ml of the prepared environment in addition to the N80 steel sample in each vial. The vials were airtight sealed, purged with nitrogen, and sterilized by autoclaving at 120 °C for 50 minutes. Then, 1 ml of the (SRB) water sample was injected through the septum of each vial.

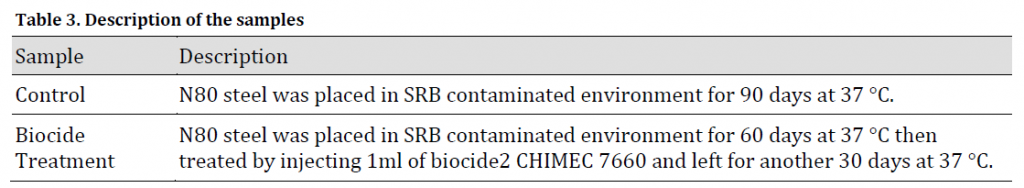

The vials containing the samples were incubated 37 °C for 90 days (Control) or treated after 60 days of incubation by injecting 1 ml of Biocide 2 CHIMEC 7660 (CHIMEC – Rome) and left in the incubator at 37°C for another 30 days (Table 3). Medium pH was measured before and after incubation for both control and treatment using PHS-3E pH Meter

SEM and EDS analysis

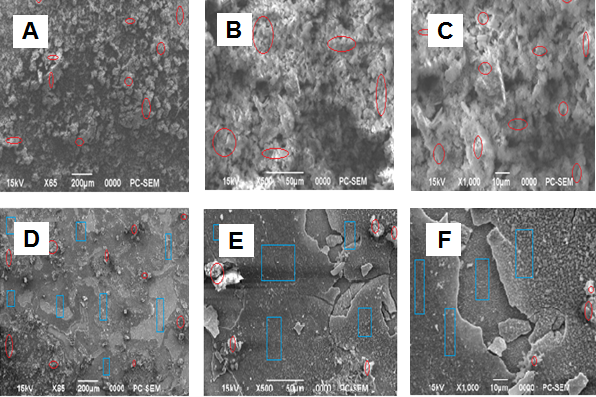

Samples surfaces were inspected using scanning electronic microscope (SEM) to determine the morphological aspects of each sample surface with magnifications of X65, X500, and X1000. Furthermore, Quanta SEM-EDS analytical system was used in order to determine the elements that contribute to the formation of this deposit.

Results and discussion

pH measurements

Results showed that the pH of the Control environment was increased from 7.1 before incubation to 9.01 after incubation, forming a more preferable environment for bacteria and thereafter, formation of biofilm clusters which can develop even under extreme conditions of temperature and hydrostatic pressure [16]. On the other hand, a decrease in pH (4.89) was observed in biocide treated sample. This low pH medium can trigger an inhibitory effect on bacterial growth with the presence of H2S [17].

Scanning electronic microscope (SEM) analysis

The morphological aspects of the formed deposits were inspected using scanning electron microscopy (Fig. 1). The surface of the control sample clearly demonstrated the existence of a stable adherent deposit in the form of colonies (Fig. 1 A, B and C); whereas large cleared areas were observed in the surface of Biocide treated sample (Fig. 1 D, E, and F). This indicates the high efficiency of the used Biocide in removing these deposits and preventing bacterial aggregation.

EDS analysis

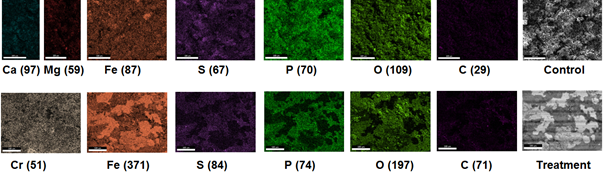

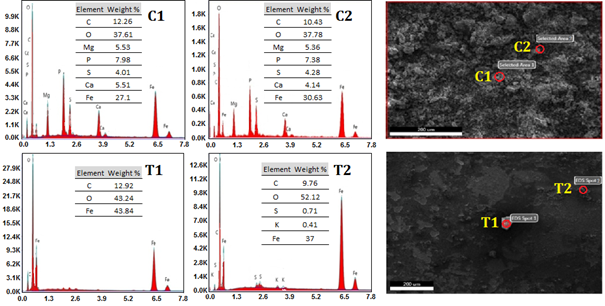

In order to understand the chemical compositions of the layer formed on N80 samples surfaces, Energy Dispersive X-ray spectrometry was used. The obtained maps were used to analyze chemical elements distribution with an allocation of color for each detected element (Fig. 2). Maps analysis results showed that the elements existed in the deposit layer were: Oxygen (O) which is here a result of water ionization, Iron (Fe) as a result of iron oxidation, Carbon (C), Calcium (Ca), Magnesium (Mg), Phosphorus (P), and Sulfur (S) which resulted from the conversion of Magnesium Sulfate and Ammonium Sulfate [7][18][19]. Sulfate-Reducing Bacteria efficiently use the compounds derived from the oxidation of sulfur as electron acceptors. These compounds such as Sulfate (SO4-2), Sulfites (SO3-2), Thiosulfates (S2O4-2), and elemental Sulfur (S°) are reduced entirely to Sulfide [18]. The biochemical reactions involved in SRB activities end with iron oxide and iron Sulfide [19] which explains the high iron oxide and Sulfide in the formed deposit.

EDS spectrum analysis for the treated sample illustrated that the main surface deposits were O, Fe, and C with 98.9% in T2 scan and 100% in T1 scan for the three elements combined with only traces of S and K; while this ratio did not exceed 78.8% for the three elements combined in control sample with 22% and 21.2% Mg, Ca, P, and S combination in C1 and C2 respectively (Fig. 3). Phosphorus and sulfur precipitates are usually interpreted as an indicator for SRB activity [20] which refers to the increased activity in the non-protected steel sample in comparison to the biocide protected sample.

Conclusions

Biocide treatment lowered pH levels for the environment rendering it unfavorable for SRB growth and biofilm-forming in comparison to the control sample.

Corrosion signs were observed in both biocides treated and untreated samples; therefore, 60 days of exposure to SRB are enough to develop bacterial corrosion in untreated N80 steel.

Although Biocide application was efficient enough to control bacterial growth and eliminate the forming residues after 60 days of exposure to (SRB), the bacterial corrosion occurred before the treatment was enough to cause damage to the studied surface which refers to the effectiveness of using Biocide 2 CHIMEC 7660 and emphasizes on its early application.

References

| 1 | Marconnet C, Dagbert C, Roy M, Féron D. Comportement d’aciers inoxydables en eaux naturelles. Mater. Tech. 2005;93:s-83. DOI |

| 2 | Maluckov BS. Corrosion of steels induced by microorganisms. Metall. Mater. Eng. 2012;18(3):223-32. |

| 3 | Chantereau J, Bouffard AM. Corrosion bactérienne-bactéries de la corrosion. 1977. |

| 4 | Videla HA, Herrera LK. Microbiologically influenced corrosion: looking to the future. Int. Microbiol. 2005;8(3):169. |

| 5 | Karr EA, Sattley WM, Jung DO, Madigan MT, Achenbach LA. Remarkable diversity of phototrophic purple bacteria in a permanently frozen Antarctic lake. Appl. Environ. Microbiol. 2003;69(8):4910-4. DOI |

| 6 | King RA, Miller JD. Corrosion by the sulphate-reducing bacteria. Nature. 1971;233(5320):491-2. DOI |

| 7 | Enning D, Garrelfs J. Corrosion of iron by sulfate-reducing bacteria: new views of an old problem. Appl. Environ. Microbiol. 2014;80(4):1226-36. DOI |

| 8 | Santegoeds CM, Ferdelman TG, Muyzer G, de Beer D. Structural and functional dynamics of sulfate-reducing populations in bacterial biofilms. Appl. Environ. Microbiol. 1998;64(10):3731-9. |

| 9 | Davey ME, O’toole GA. Microbial biofilms: from ecology to molecular genetics. Microbiol. Mol. Biol. Rev. 2000;64(4):847-67. DOI |

| 10 | Busscher HJ, van der Mei HC. Microbial adhesion in flow displacement systems. Clin. Microbiol. Rev. 2006;19(1):127-41. DOI |

| 11 | Galvão M, Lutterbach MT. Application of the qPCR technique for SRB quantification in samples from the oil and gas industries. Applications of molecular microbiological methods. Skovhus TS, Caffrey SM and Hubert CRJ (eds.), Caister Academic Press. 2014;215:69-77. |

| 12 | Hulak I. Protection contre la dégradation et la prolifération des microorganismes. XXIIe Journée Technologique. Les polymères à usage médical. 1999. |

| 13 | Uliasz M. Wykorzystanie związków aminowych w technologii płuczek wiertniczych. Nafta-Gaz. 2010;66(7):577-85. |

| 14 | Turkiewicz A, Brzeszcz J, Kapusta P. The application of biocides in the oil and gas industry. Nafta-Gaz. 2013;69(2):103-11. |

| 15 | Tanner RS. Monitoring sulfate-reducing bacteria: comparison of enumeration media. J. Microbiol. Methods. 1989;10(2):83-90. DOI |

| 16 | Normand B. Prévention et lutte contre la corrosion: Une approche scientifique et technique. PPUR presses polytechniques; 2004. |

| 17 | Koschorreck M. Microbial sulphate reduction at a low pH. FEMS Microbiology Ecology. 2008;64(3):329-42. DOI |

| 18 | De Beer D, Stoodley P, Roe F, Lewandowski Z. Effects of biofilm structures on oxygen distribution and mass transport. Biotechnology and bioengineering. 1994;43(11):1131-8. DOI |

| 19 | Marty D, Bertrand JC, Caumette P. Les métabolismes bactériens dans les systèmes sédimentaires marins. Microorganismes dans les écosystèmes océaniques. Masson, Paris, France. 1989:101-51. |

| 20 | Prithiraj A, Otunniyi IO, Osifo P, van Der Merwe J. Corrosion behavior of stainless and carbon steels exposed to sulphate–reducing bacteria from industrial heat exchangers. Engineering Failure Analysis. 2019;104:977-86. DOI |

Cite this article:

Dekhili, N. The effect of biocide 2 CHIMEC 7660 on N80 steel corroded by bacterial corrosion. DYSONA – Applied Science, 2020; 1(1): 29-35. doi: 10.30493/das.2020.103719